ABOUT US

Myanmar Yi Jin is a China-Myanmar joint venture company, founded in 2016 and located in Hlaing Thar Yar Township, Yangon, Myanmar. The company occupies a 15-acre site (60,000 square meters) and has constructed its own factory warehouses, office buildings, dormitories, and other infrastructure using its own steel structure systems.

OUR BUSINESS SERVICES

Myanmar Yi Jin is a one-stop solution provider in the steel construction industry. We offer professional services in design, fabrication, and construction of steel structures for warehouses, industrial plants, and commercial projects.

OUR CORE PROCESS

Our steel structure services cover the full process—from design to installation. Once designs are approved, components are fabricated in our facility with CNC cutting, precision welding, and forming lines under strict quality control. We ensure timely delivery through reliable logistics and crane services, followed by on-site installation by experienced engineers who follow rigorous safety standards. This end-to-end approach guarantees durable, efficient, and high-quality steel structures for every project.

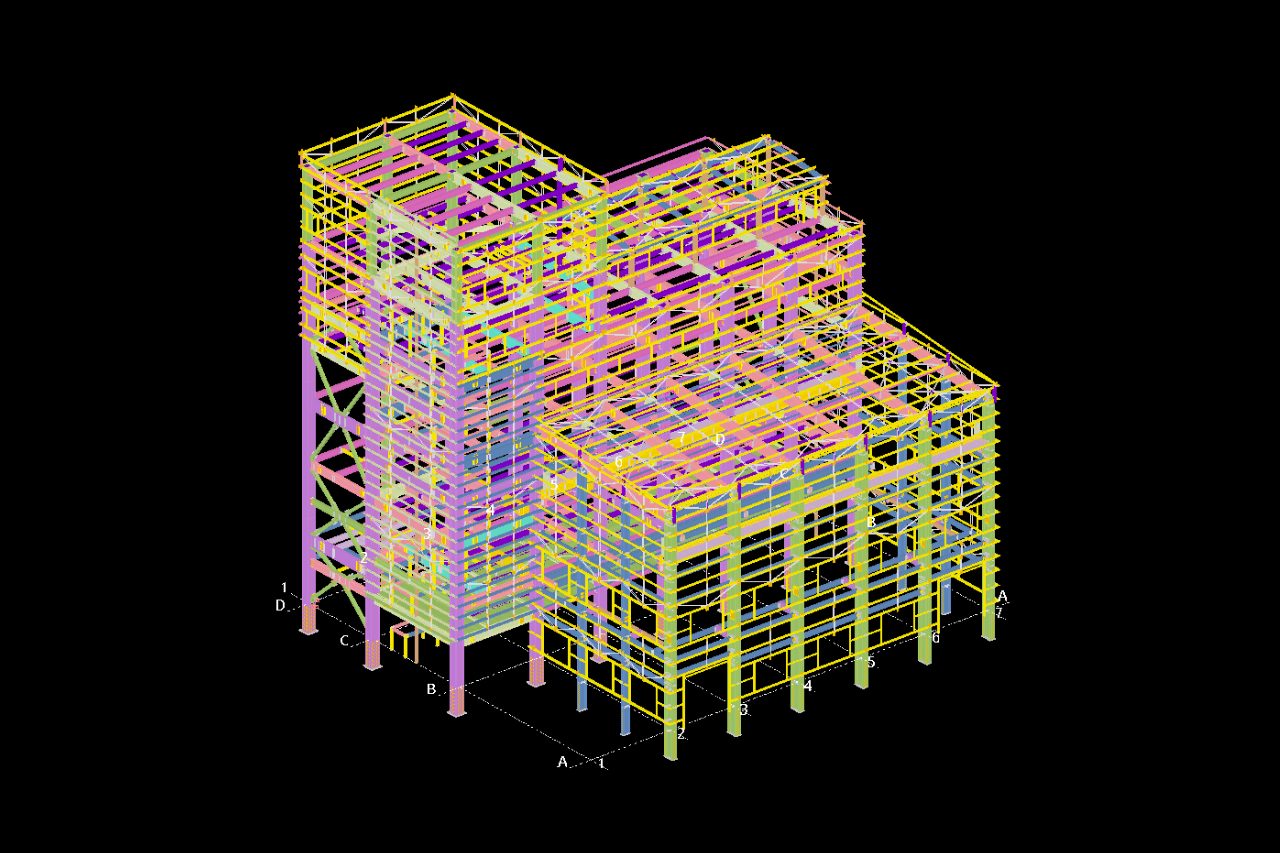

Structural Design & Engineering

At Myanmar Yi Jin, every structure begins with intelligent, code-compliant design. Our design team conducts advanced structural analysis and detailing using professional engineering software to ensure strength, safety, and long-term performance. From layout planning to load calculations, we carefully tailor each design to meet the project’s functional requirements and environmental conditions—laying a rock-solid foundation for everything that follows.

Precision Fabrication Process

With precision as our priority, our in-house steel fabrication facility transforms design into reality. We use CNC cutting machines, automated drilling, and welding systems to shape and prepare components with exacting accuracy. Every piece is fabricated to meet international quality standards—guaranteeing consistency, durability, and seamless fit during assembly on-site.

OUR PROJECTS

We are proud to be behind some of Myanmar’s most iconic steel structure projects. From national landmarks like Zayarthiri, Wunna Theikdi, and Mandalarthiri Stadiums to key developments such as the Mandalay Jade Gem Market and Mandalay Convention Center, our work reflects strength, scale, and a deep commitment to building for Myanmar’s future.

NATIONAL KEY PROJECTS

MANDALAY CONVENTION CENTER

The construction area is 31,000 square meters, the frame structure, and the amount of steel used is 5200 tons. The project is characterized by a large thickness of components, the maximum thickness of 125mm thickness, the difficulty is that the welding process requirements are high, the weld level is a first-class full penetration welding, on-site installation, large tonnage crane floor operation and ultra-long.

2013 Southeast Asian Games Stadium

The host stadium for the 2013 Southeast Asian Games spans 56,019 square meters, with a construction area of 32,000 square meters. Designed with an oval plan and a saddle-shaped curve, it features a projection line of 263m (long axis) by 213m (short axis). Rising to a height of 24.25m, the stadium accommodates 30,000 spectators. Built with 4,780 tons of structural steel, it stands as a landmark in modern sports architecture.

MANDALAY JADE MARKET

The construction scale of phase I is 11661 square meters, including jade market, restaurant, office building, jade processing plant, staff dormitory, equipment room and six combined buildings. Phase II includes indoor and outdoor fine decoration, water and electricity, fire protection, air conditioning and surrounding municipal works.

OUR vALUED CLIENTS

Plan Your Steel Structure With Confidence

From the ground to the final structure, we guide you through every step — professionally, reliably, and built strong to meet your needs.